Potato Chips Making Machine

Product Details:

- Material Stainless Steel

- Automatic Yes

- Control System PLC Control

- Installation Type Free Stand

- Click to View more

Potato Chips Making Machine Price And Quantity

- 1 Set

- 4000000 INR/Set

Potato Chips Making Machine Product Specifications

- PLC Control

- Stainless Steel

- Yes

- Free Stand

Potato Chips Making Machine Trade Information

- 1 Set Per Month

- 30 Days

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

INDUSTRIAL SOLUTIONS FOR PROCESSING & PACKAGING POTATO CHIPS

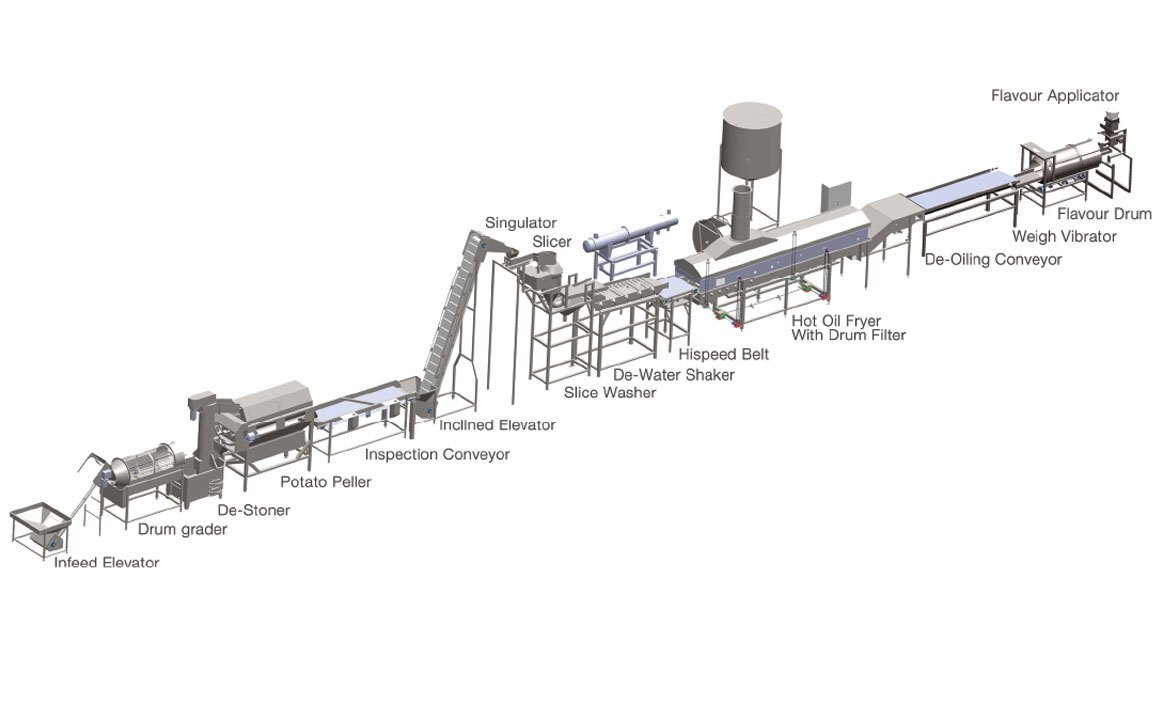

AUTOMATIC POTATO CHIPS PRODUCTION LINE

Producing theworlds best tasting potato chips, our industry leadingend-to-end systems process and package the highest quality potato chip products.

Capacity - 300 kg/hr 500 kg/hr 750kg/hr and 1000 kg/hr

Potato Unloading & Storage

Raw potato handling is simplified as it enters the facility with equipment to unload and store potatoes prior to processing. Truck dumpers, dirt removers, transfer, and bin storage systems handle large volumes of potatoes easily and gently.

Peeling / Grading

Achieve peeling control and high yield with batch or continuous peeling systems that deliver polished peeled potatoes and minimal peel loss. Inspection conveyors provide operator friendly access and full visual inspection.

Blanching

Blanch potato slices before they enter the fryer. All blanching systemsare designed to remove sugars from potato slices to produce lighter color chips as well as remove fines before the fryer. Washers are designed to separate slices, eliminate clusters, and feed a mono-layer of slices across the width of the fryer for uniform cooking.

Frying

We provide more choices when it comes to selecting a new fryer. Choose from natural gas, oil, steam, thermal fluidor electric heating. Optimal product handling, uniform oil heatingand flow control, efficient fines removal, fast oil turnover, and clean-in-place sanitation are all part of the fryer package that produces the highest quality product with a long shelf life.

Seasoning

Our unbeatable seasoning showcase includes a variety of systems that provide consistent anduniformseasoning coverage for all kinds of snack foods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Potato Chips Making Machine' category

|

GRACE FOOD PROCESSING & PACKAGING MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free Send SMS

Send SMS